What is the CME Office?

Personal Protective Equipment (PPE) and its key chemicals and components were not produced by U.S.-based industries, and, prior to the COVID-19 pandemic, the PPE supply chain was not a focus for the U.S. government (USG). As the pandemic response matured, USG efforts shifted toward building an end-to-end domestic supply chain for PPE – from key chemicals to intermediate materials to final manufacturing, packaging, and distribution and, ultimately, the formation of the Industrial Based Management and Supply Chain (IBMSC) Critical Medical Equipment (CME) office. The COVID-19 pandemic has highlighted critical vulnerabilities in the global public health supply chain as it relates to critical medical equipment. The CME office works steadfastly toward building a more robust, agile, and transparent critical medical equipment supply chain capable of responding effectively to a global health crisis.

CME in Action

-

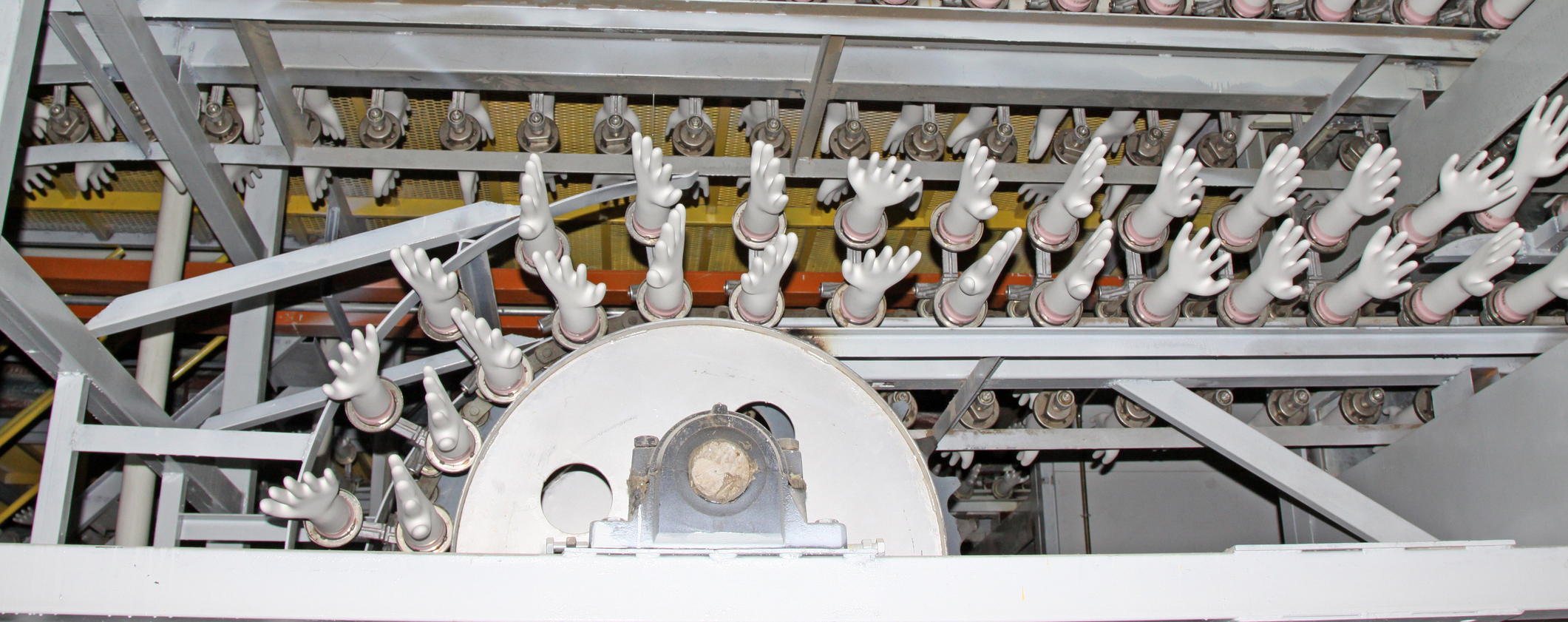

Invested $1.4 billion in PPE-related contracts, including nitrile glove and gown production, surgical and N95 masks, melt-blown fiber and nitrile butadiene rubber, ensuring the United States government is able to provide PPE when America needs it most.

-

The total value invested in PPE is ~$980M+.

-

Invested in industrial base expansions of N95 Respirators, surgical masks, nitrile gloves and gowns.

-

Managed 17 total contracts with 7 still active and several pending award.

-

Working on sub tier supply chain materials such as key chemicals and Nitrile Butadiene Rubber (NBR) used to make the gloves.

-

Supports the Make PPE in America act by working to ensure all the components of the PPE are also domestically manufactured so there are PPE-compliant products available to be purchased and meet the requirements of this act.

Future Focus

-

Increase Domestic Manufacturing: Expanding domestic production of critical supplies like N95 respirators, nitrile gloves, and the raw materials required for their production is essential for ensuring supply chain resilience.

-

Strategic Stockpiling: Developing strategies for warm-basing activities and collaborating with the SNS for strategic stockpiling that can help maintain surge capabilities and meet emergency demands.

-

Innovative Solutions: Exploring new technologies in next generation PPE, and manufacturing processes to improve efficiency and reduce dependency on volatile raw materials.

-

Public-Private Partnerships: Strengthening collaborations between the government and the PPE manufacturers to enhance supply chain agility and robustness.

-

Global Cooperation: Working with international partners to ensure a coordinated response to global supply chain challenges related to PPE.

Why is the CME Office Important?

The COVID-19 pandemic made clear the need to reduce national reliance on essential foreign goods, including PPE. The CME office ensures that when a public health emergency arises, the United States government and the health care sector can acquire domestically produced sources of critical medical equipment to protect first responders and the American people. The federal government is committed to advancing Made in America objectives and implementing acquisition programs to support long-term sustainability of the domestic PPE manufacturing industry. The CME office ensures that this commitment becomes a reality by developing acquisition strategies to create a more robust, agile, and transparent supply chain capable of responding effectively to a global health crisis.